The basics of foil stamping process.

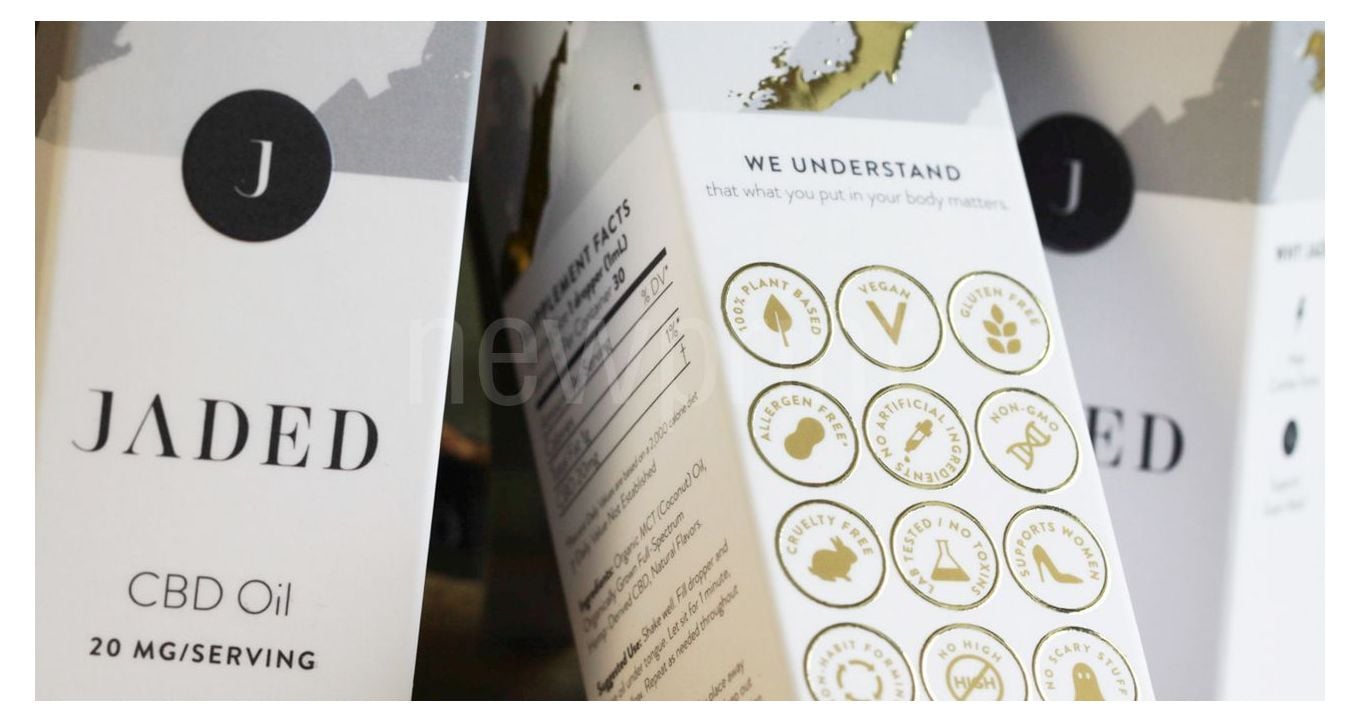

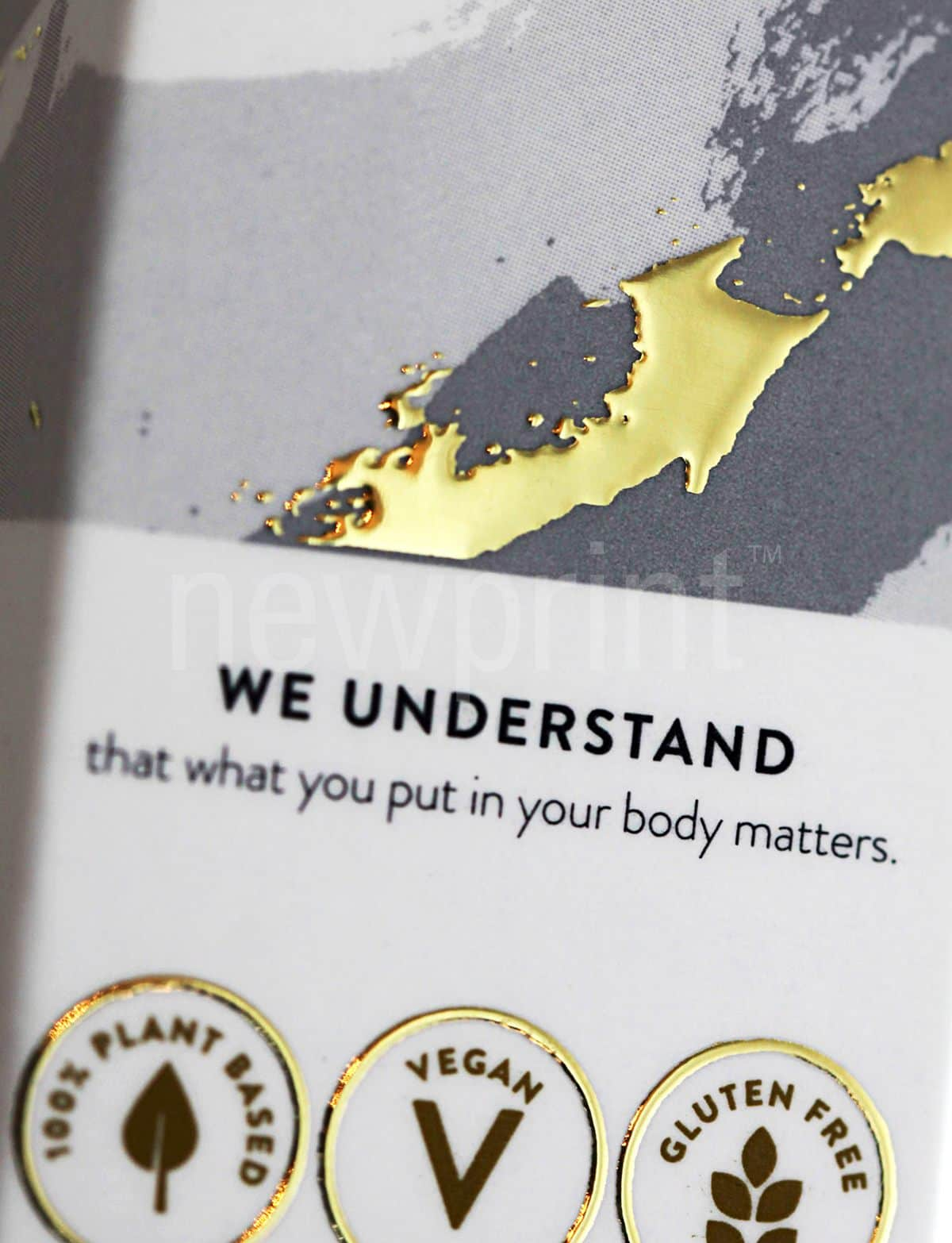

Foiling is a great way to make your print material look unique and sophisticated, to add more class and make the product look premium.

How Does Foil Stamping Work?

Foil stamping is a process that traditionally uses heat, pressure and foil. The foiling elements of your design are engraved onto a heated foiling die (it is like a rubber stamp, but made of metal). A roll of thin foil is placed between the die and your substrate (paper), and pressure is applied.

What is the Purpose of Foil Stamping?

Foil stamping is going to make your product stand out. Studies have shown that the more appealing the product looks, customers are going to pay more attention. Foil is going to make your product hard to put down and ignore. It will make your product look prestigious and will be associated with superior quality. This is especially important for luxury products, as the packaging needs to reflect the premium qualities of the product itself. But foil stamping is not only used for product packaging. It is commonly seen on various print products such as business cards, high-end marketing collateral, greeting cards, or books.

What are the Most Popular Foil Colors?

The most popular foils are gold and silver, but they also come in many other colors and effects. After foiling, you can apply different finishes to make it stand out even more.

The luxurious feel of foiling comes from the usage of real gold leaves on old manuscripts. The technique is later adapted to be more affordable, but the feeling of luxury that we experience when we see gold and silver is still there.

What are the Different Types of Foils?

There are a few different types of foil:

Metallic Foils are mostly used for silver, gold, copper and bronze appearance. But they also come in different colors, such as purple, red, blue, green and others. They can be glossy (shiny), and have a “mirror-like” shine. Satin refers to metallic foils that have “blurry” reflections. Satin provides a more sophisticated look and retains its base color better than gloss foil. Gloss foil reflects lights stronger and works better for small details.

Pigment Foils provide the non-metallic glossy or matte look. It is usually used for printing on textured or dry paper. A layer of pigment foil will create a solid base and ensure strong and rich color reproduction on problematic printing surfaces.

Pearl Foils achieve the more subtle, almost transparent shine without added color. They are commonly used on wedding invitations.

Holographic Foils are making a holographic or rainbow appearance in the presence of light.

Difference between foil stamping and foil printing

Hot foil stamping is a process of applying gold foil elements using a heated die and pressure. The die has the printing elements engraved and they are transferred onto the substrate by placing the foil between the die and the substrate and applying pressure. This is an off-line process, meaning the sheets are first printed using one machine, and then moved to a separate machine that does the foiling.

Foil printing, often referred to as cold foil printing, uses an ultraviolet-curable adhesive. This adhesive is applied using a standard printing plate and it will hold the foil elements. The foil web travels through the printing station using a system of rollers. The adhesive sticks and holds the parts of the foil web where it’s applied, and the remaining foil is mounted back on the rewind roll. This is an in-line process so applying color and foil is done in one pass.

Is foil stamping expensive?

There are many variables to factor in when calculating the price of foiling so it is impossible to give a general estimate on the cost of foiling. But it will definitely increase the price of printing. The final price will depend on the area the foil covers, the print quantity, the quality of the materials used, etc. Plus, hot foil stamping requires producing a die tool, which can cost anywhere between $100 and $300 in most cases. The price of foil stamping will always depend on your specific needs and demands, but as a very general guideline, foil stamping can increase the price of printing by 30% to 60%.

How to Set-up Your Print Files for Foil Stamping

Only vector-based shapes and text can be foiled. To avoid the missing fonts problem, make sure the text is outlined. Furthermore, all the artwork elements you want to be foiled need to be 100% black and placed on their own layer. That means your artwork needs to have two separate layers: one layer contains CMYK or Pantone artwork, and a separate layer contains the foil stamp elements.

When submitting the files to your printer, you need to have three separate PDF files:

- A file that contains only the CMYK / Pantone layer.

- A file that contains only the foil stamp layer.

- A file that contains both layers.

For more information, check out our detailed explanation on How To Set Up Print Files For Gold Foil Printing.