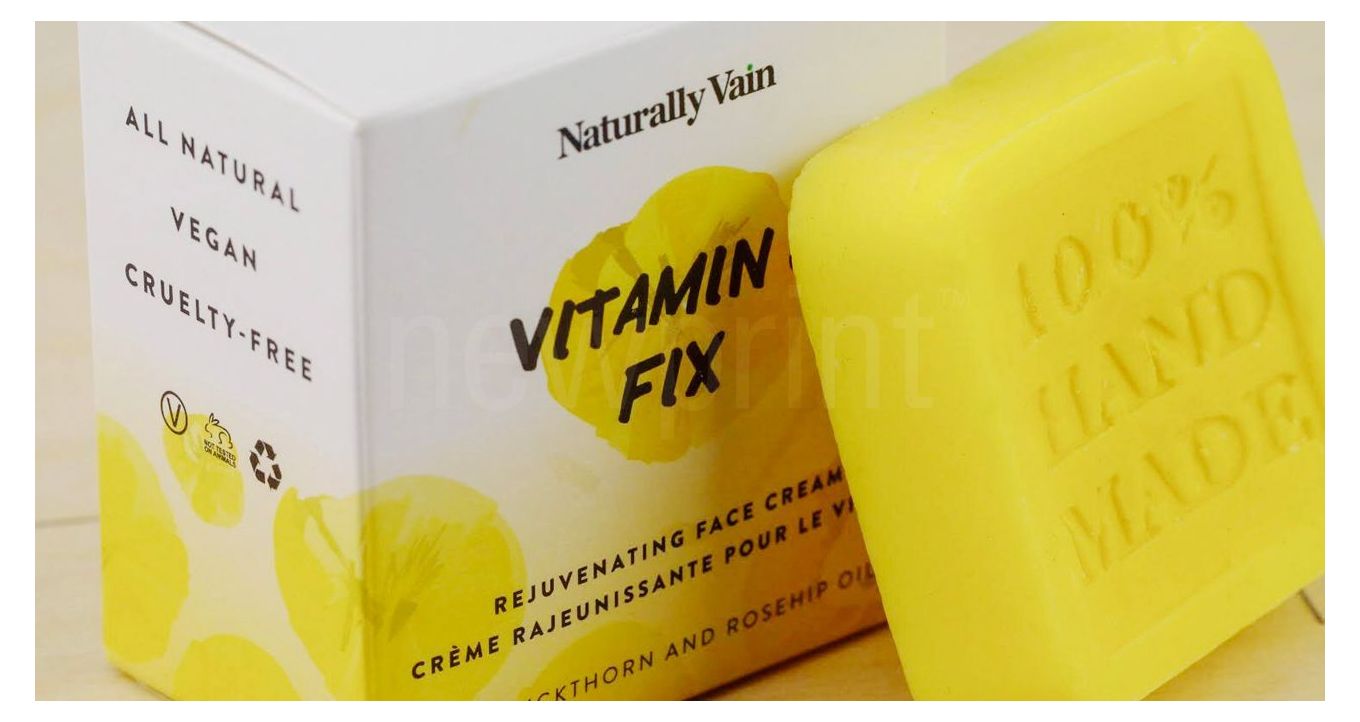

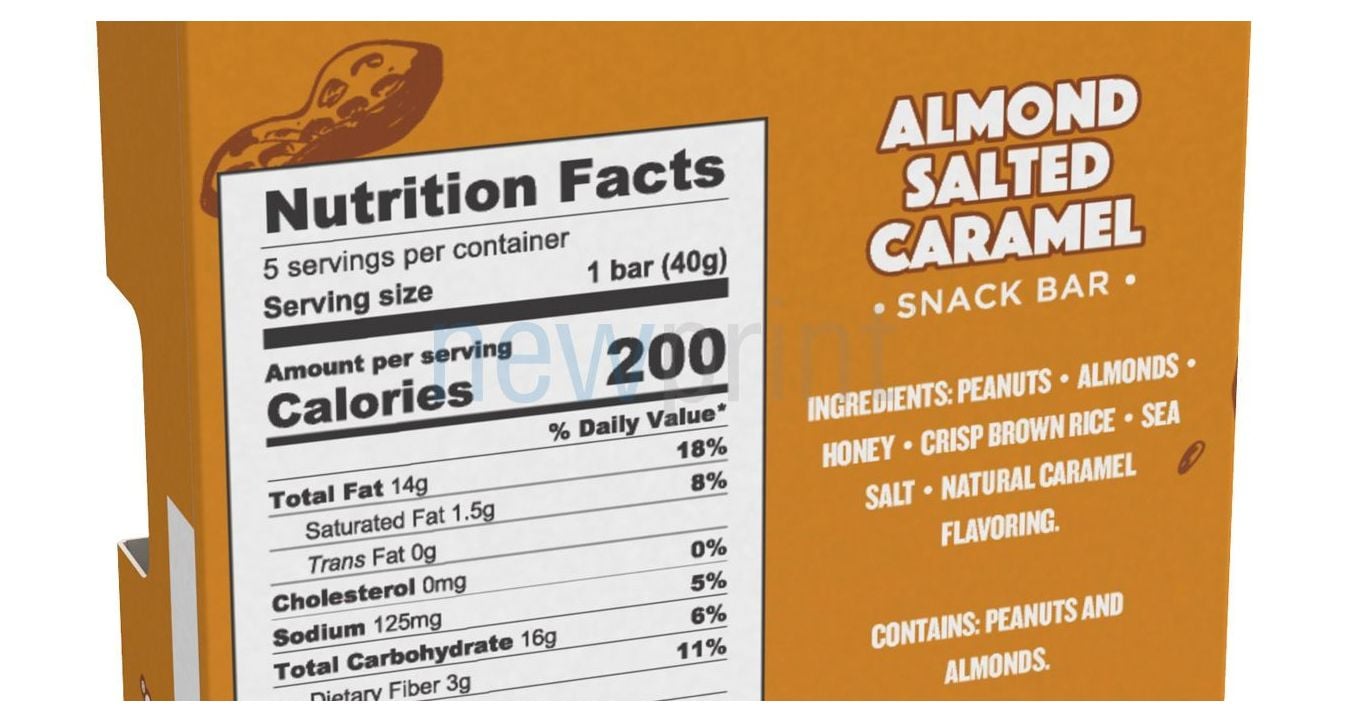

Standardization and custom product packaging boxes can exist together. ECMA standards will help you achieve the best results with your product packaging boxes.

Living in a time that promotes uniqueness and having everything tailored to our needs, people tend to look at standardization with disapproval. We are so caught up in trying to create the perfect product, something that our customers will see as the only possible answer to their needs, that we automatically look down on anything that has the word standard in the title. But, ECMA standards are not there to make all the product packaging look the same. Their function is something completely different.

Why We Need ECMA Standards?

Doing business on the global market has created the need for codes that people in different countries and industries will understand without the danger of the message getting lost in translation. So if you have ever felt like you and your business partners speak different languages, standards are there to avoid just that. And also to make sure that you will get high-quality product packaging. And that is very beneficial, don’t you think?

How ECMA Standards Can Help Improve Your Product Packaging

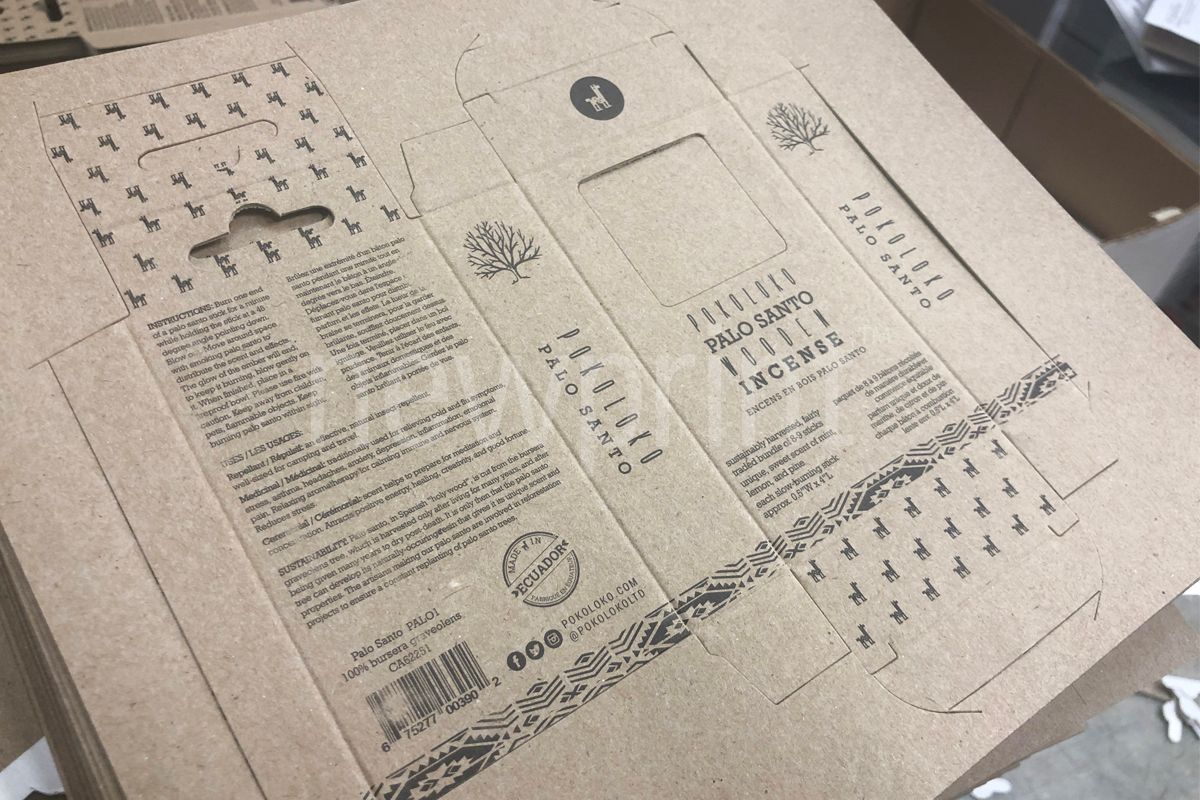

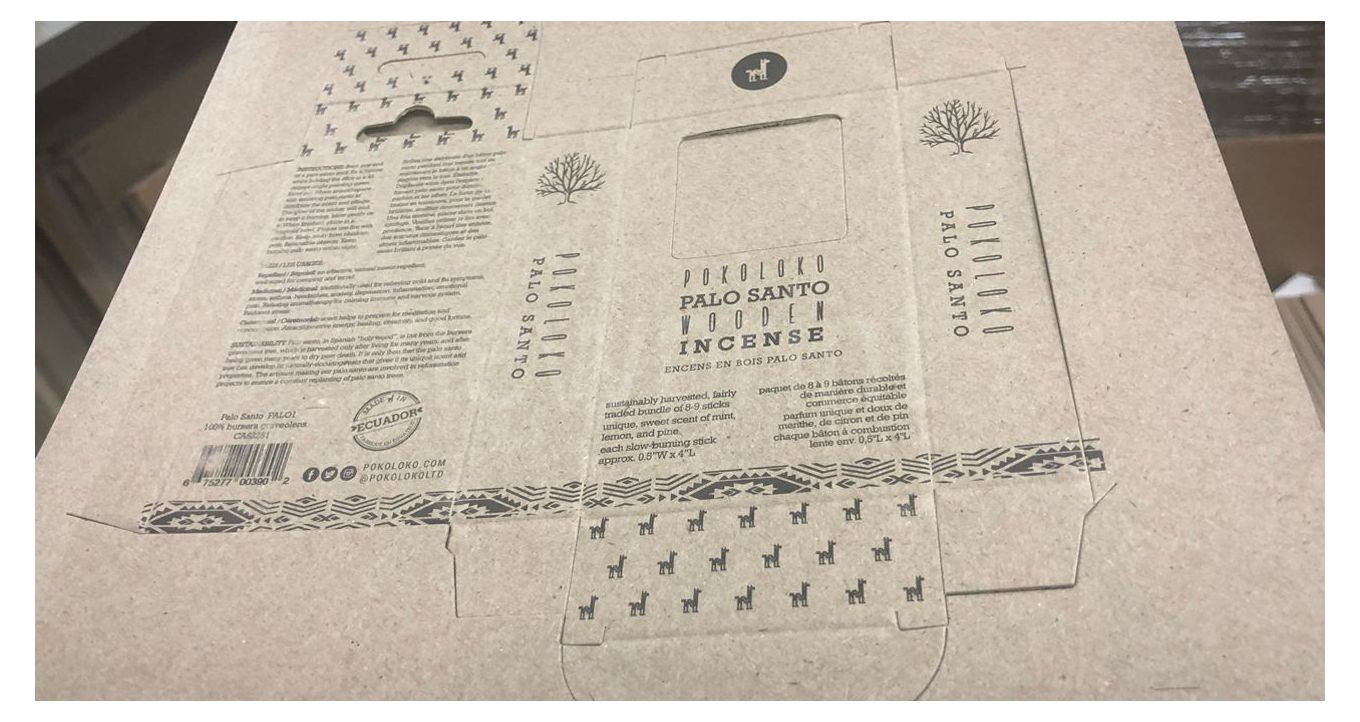

ECMA is the international network for businesses involved in the folding carton industry. It is dedicated to supporting the healthy development of the folding carton industry, developing best practices in the industry and providing advanced international standards. Although ECMA is based in Europe, they have partners in North America, and their ECMA codes of folding carton designs are recognized and used worldwide. Since folding cartons are one of the most eco-friendly product packaging options on the market, it is important to encourage businesses to use them by making their custom product packaging boxes as good as they can be.

ECMA Carton Styles Explanation

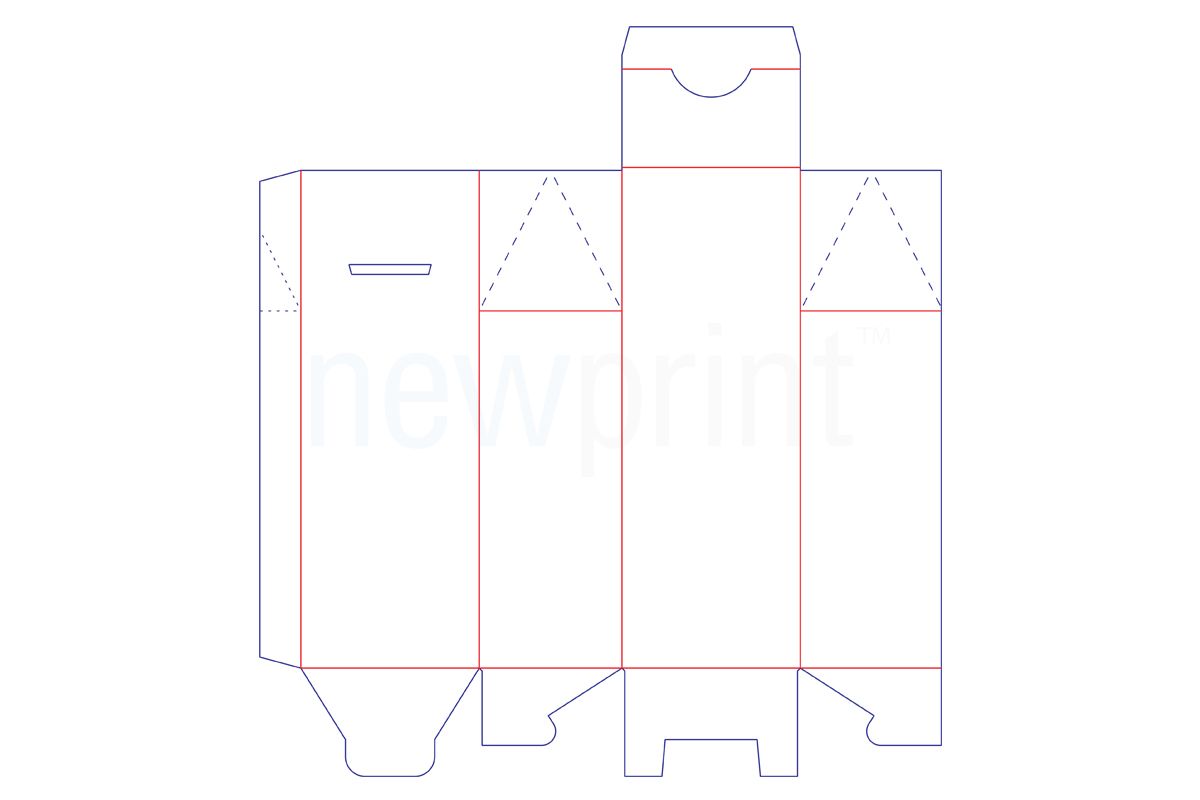

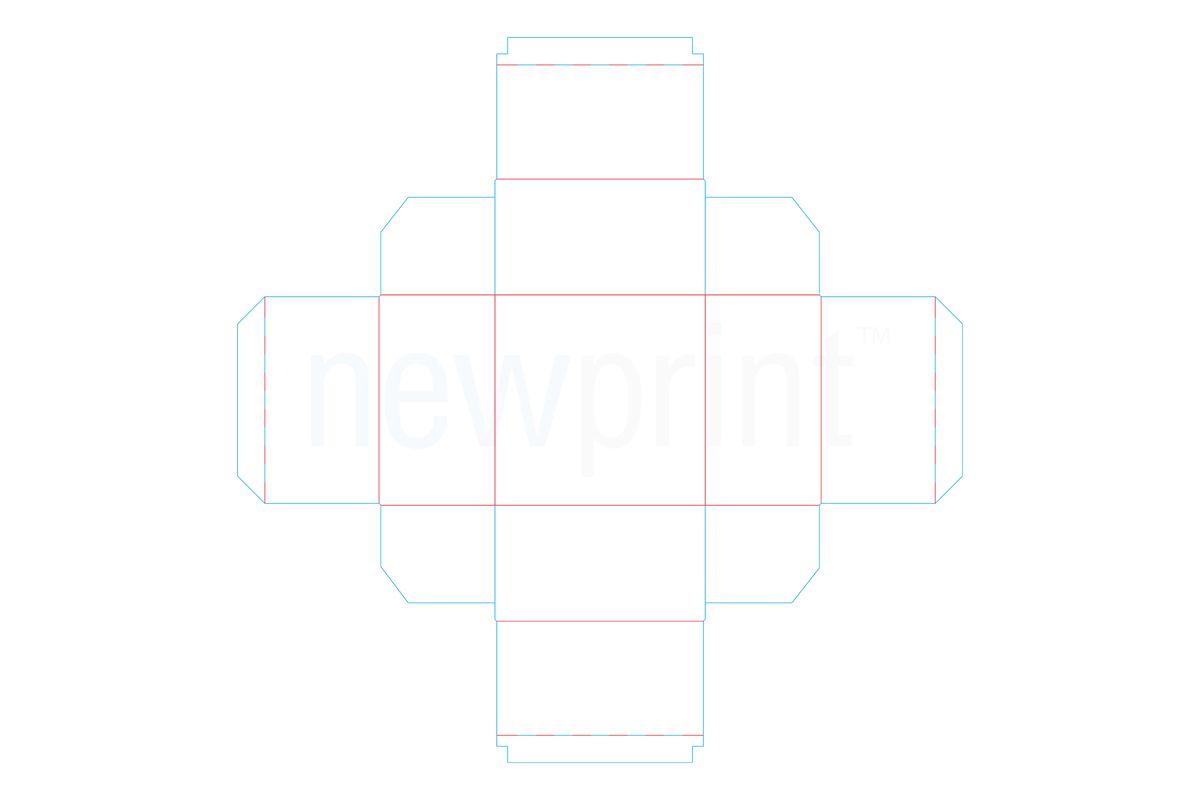

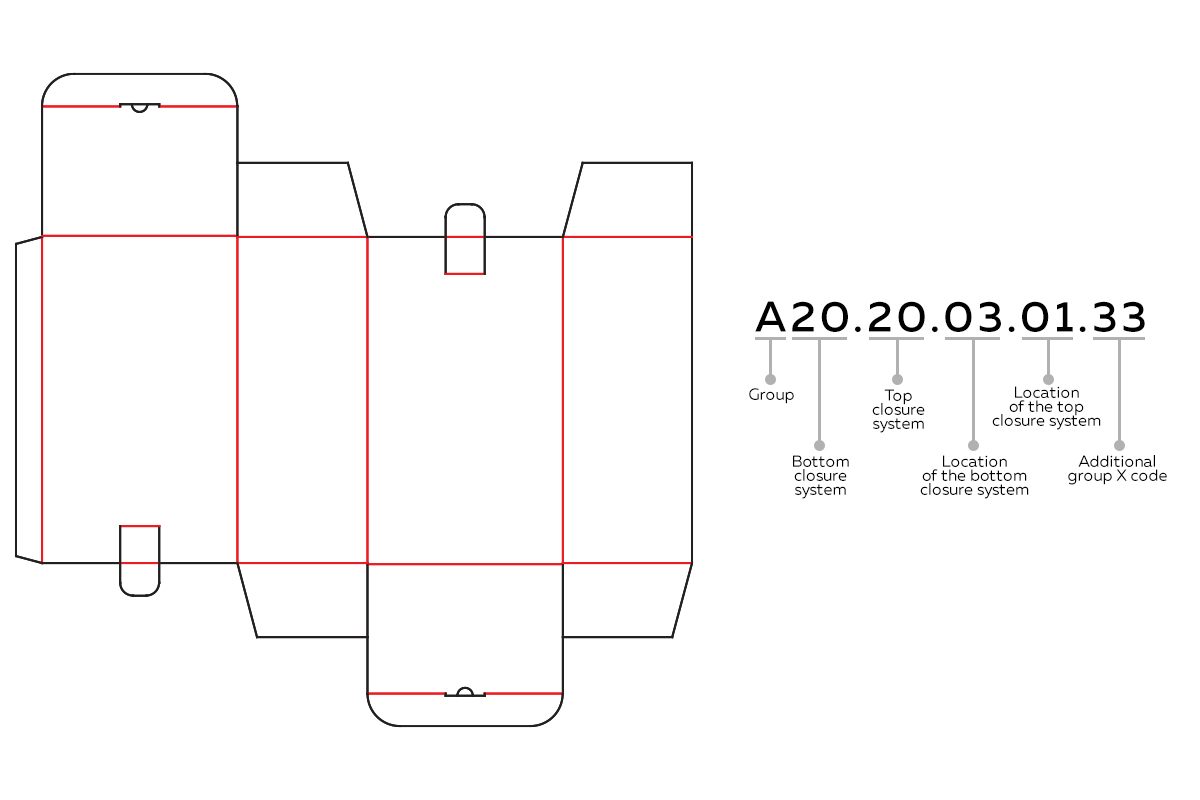

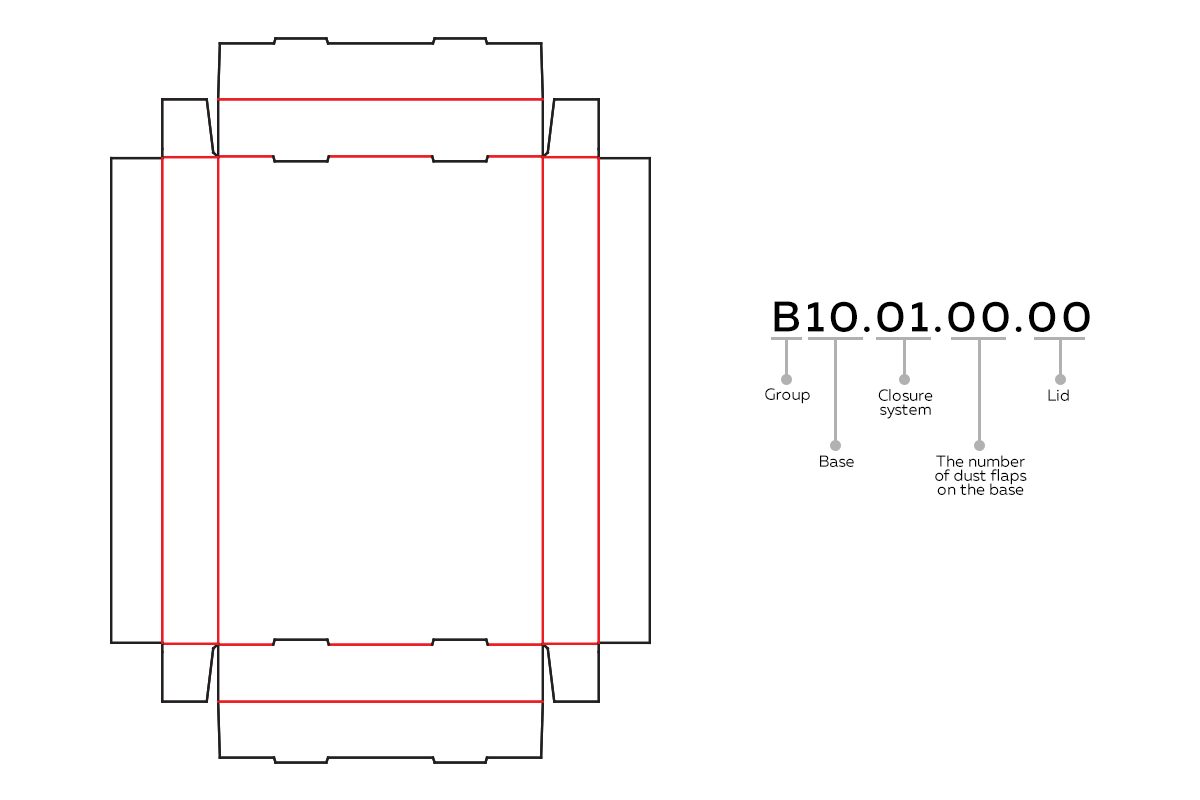

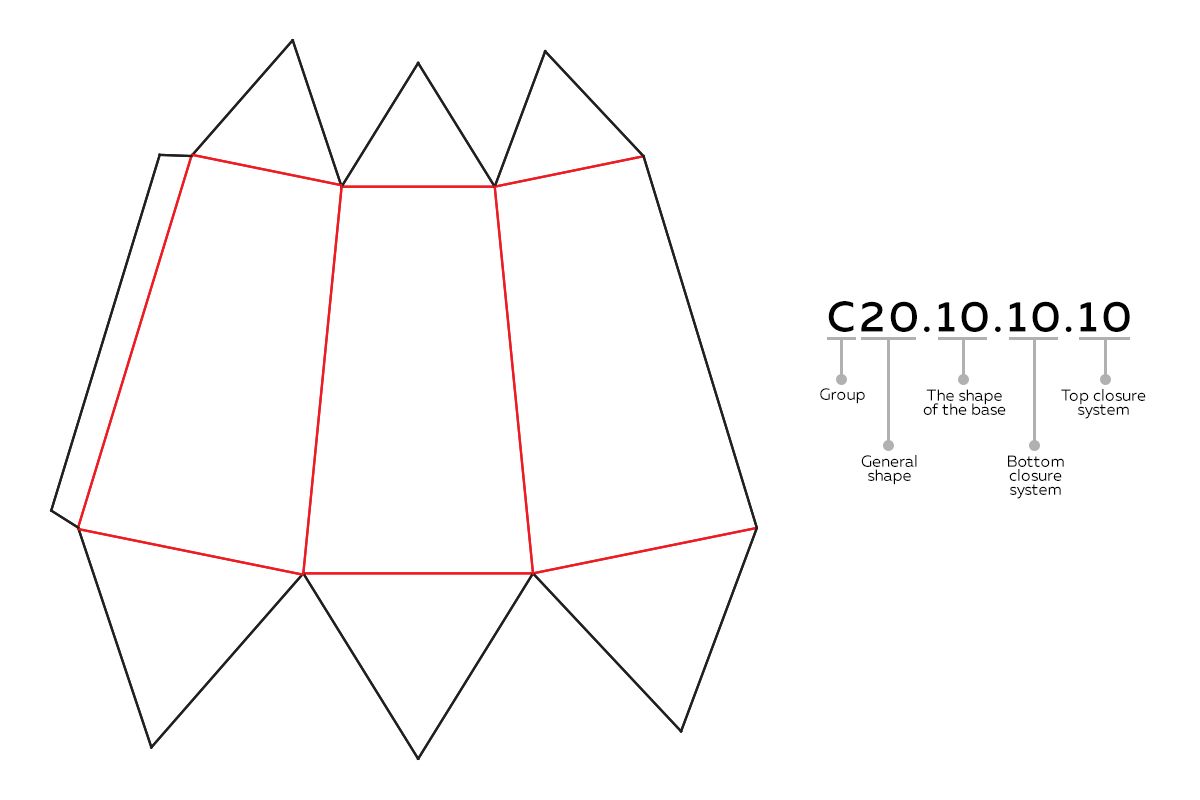

In ECMA carton styles, there are six groups of box styles. Five pairs of codes represent additional explanation. So, the ECMA code begins with the letter that determines the group, followed by four main groups of two digits that help determine the style of the box. The fifth group of numbers is known as additional group X and represents specific devices that can be used with all models of the groups A to D and some models of the last group (F). If any of the elements are not used, that pair in the code will be 00.

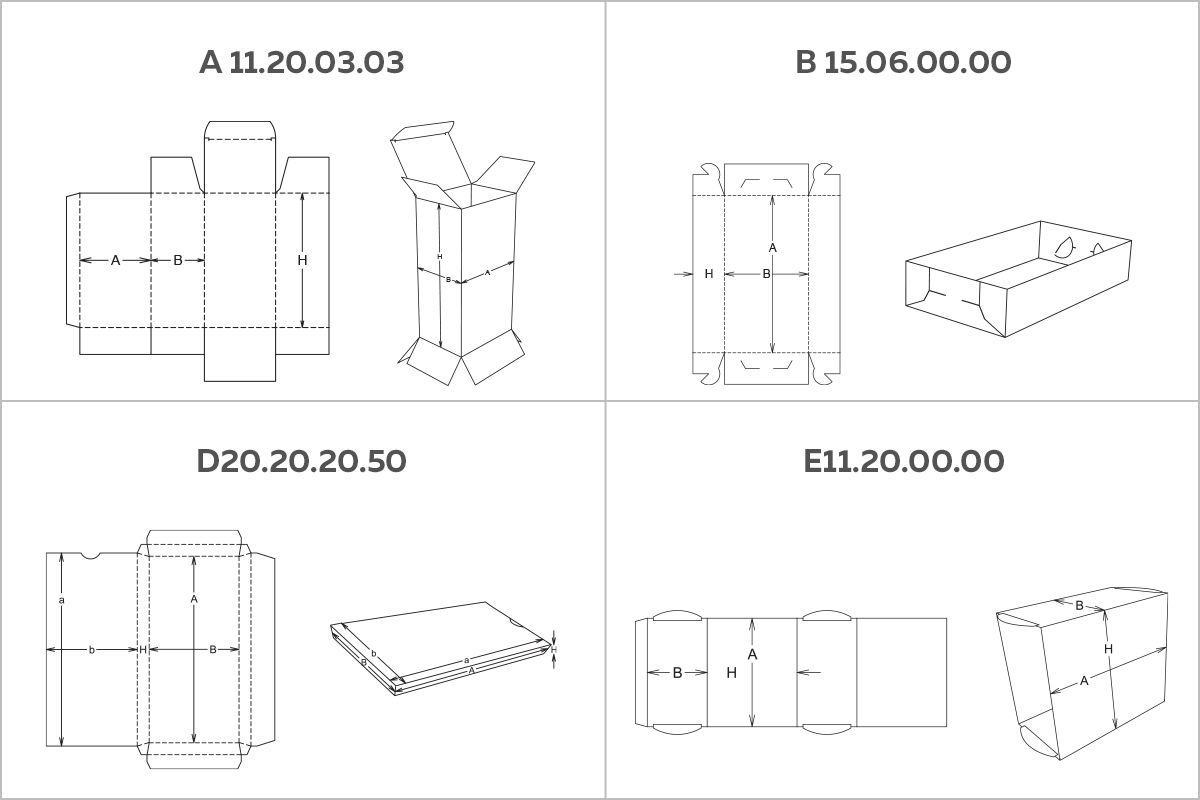

What ECMA Carton Styles Exist for Your Custom Product Packaging Boxes

A - Long Seam Rectangular Boxes, With Glue Along a Larger Dimension

- First pair - the bottom closure system

- Second pair - the top closure system

- Third pair - location of the bottom closure system

- Fourth pair - location of the top closure system

B - Short Seam Rectangular Boxes, Without Longitudinal Gluing

- First pair - the base.

- Second pair - the closure system

- Third pair - the number of dust flaps on the base

- Fourth pair - the lid.

C - Long Seam Non-Rectangular, With Glue Along the Larger Dimension and at Least One Non-Rectangular Outer Face of the Main Body

- First pair - the general shape.

- Second pair - the shape of the base.

- Third pair - the bottom closure system.

- Fourth pair - the top closure system.

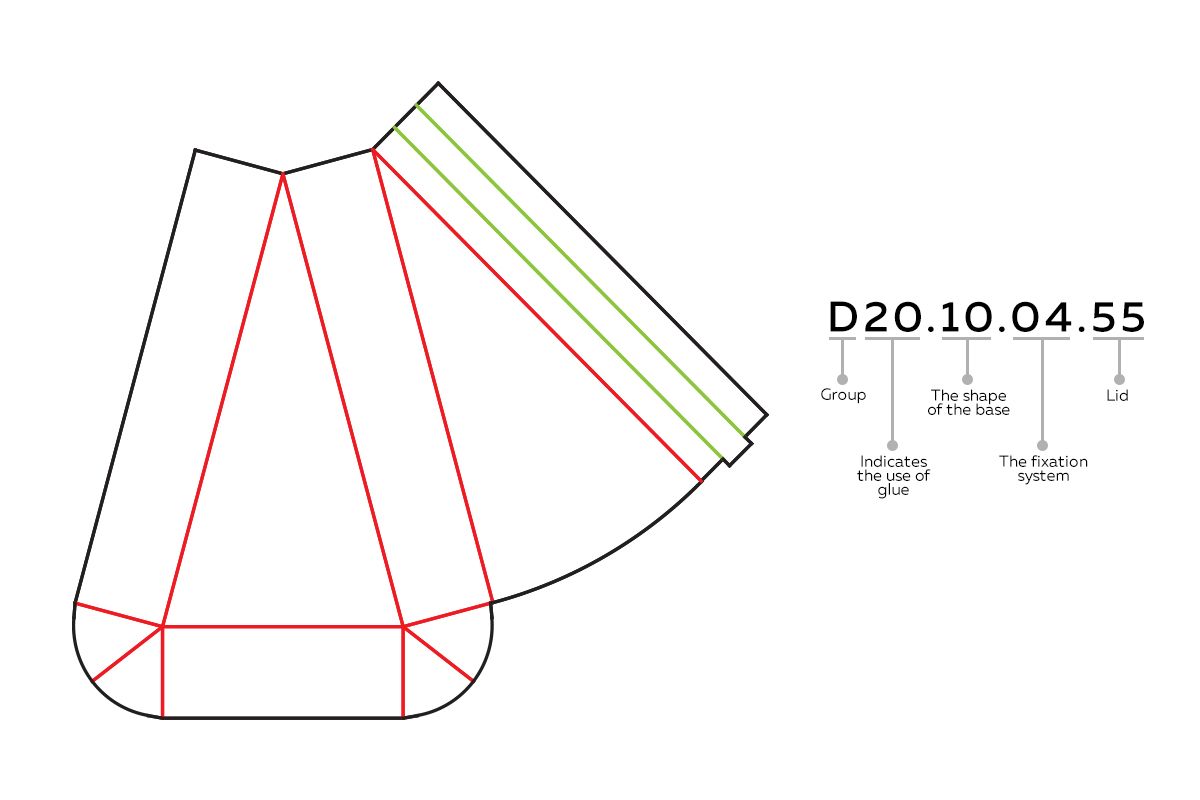

D - Short-Long Seam Non-Rectangular, without Longitudinal Gluing

- First pair - indicates the use of glue.

- Second pair - the shape of the base.

- Third pair - the fixation system.

-

Fourth pair - the lid.

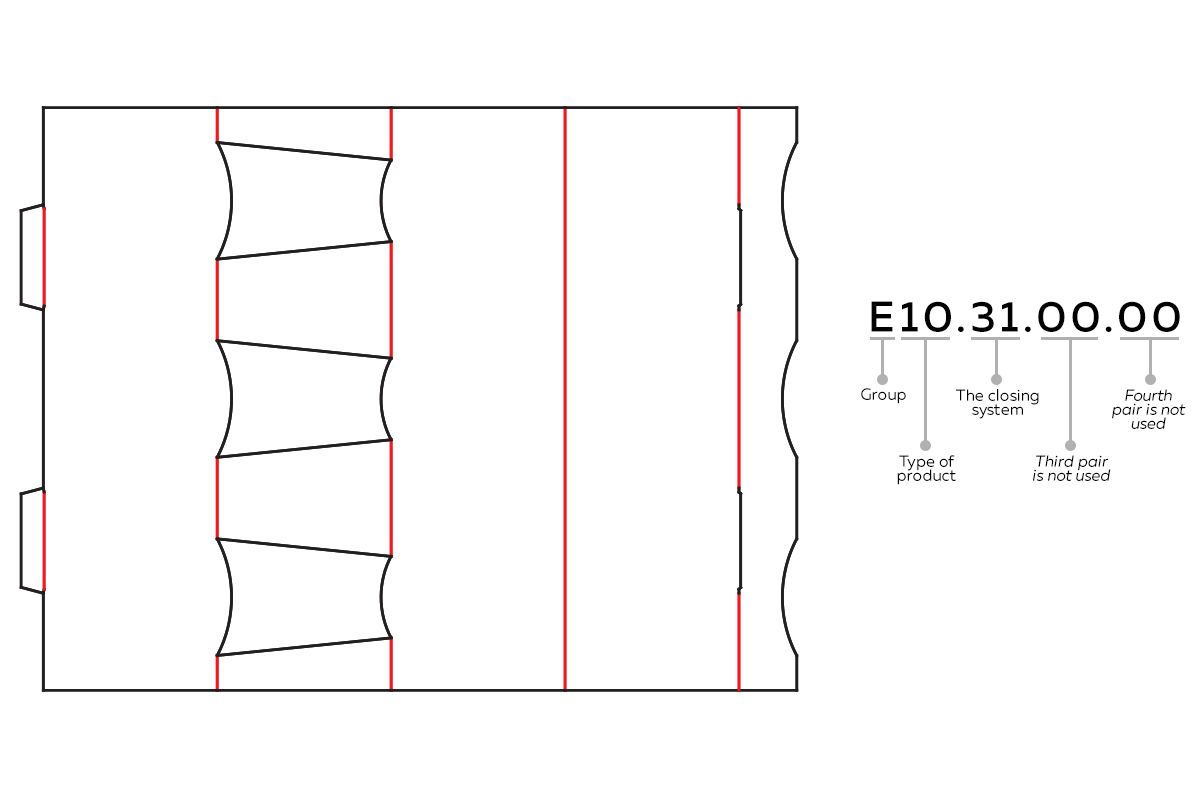

E - Product-Integrated Cartons That Are in Direct Contact With the Product or Intended for Group Packaging.

- First pair - the type of product

- Second pair- the closing system.

- Third pair is not used

- Fourth pair is not used

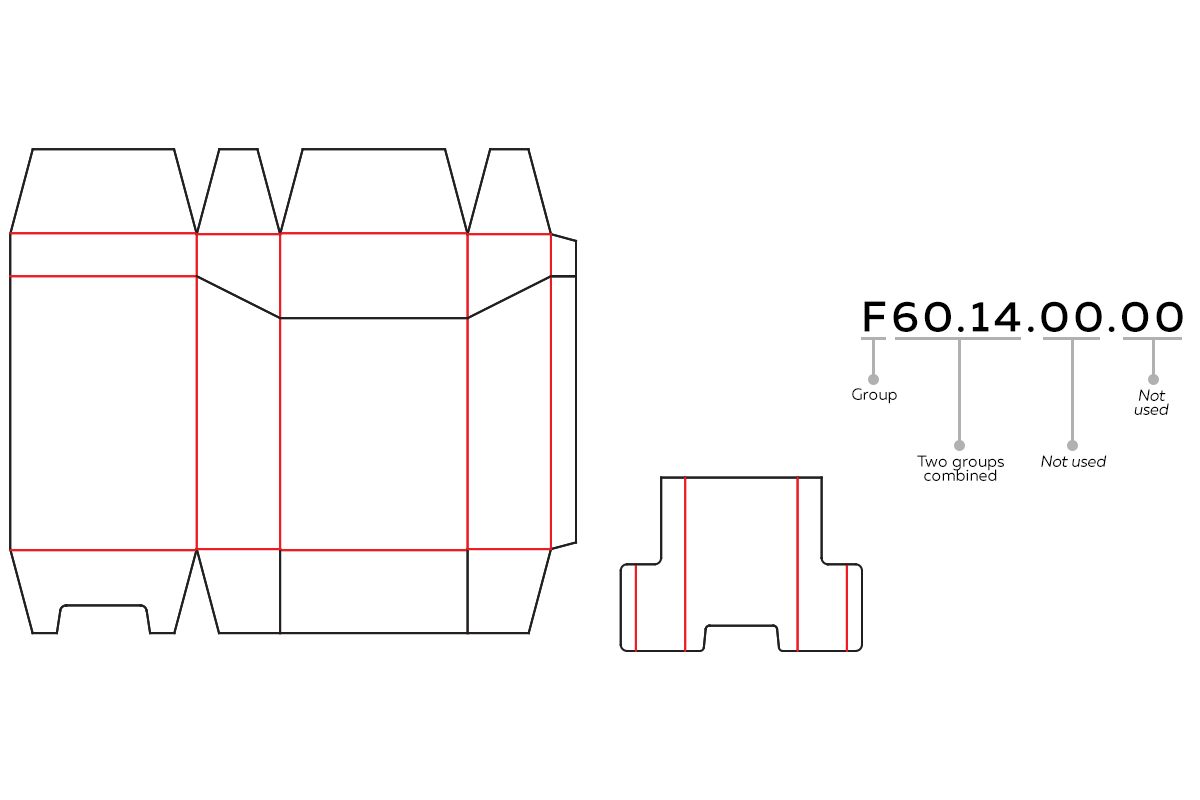

F - Other Folding Cartons That Cannot Be Placed in Any Other Group

- 10 – Special model similar to group “A”.

- 20 – Special model similar to group “B”.

- 30 – Special model similar to group “С”.

- 40 – Special model similar to group “D”.

- 50 – Special model similar to group “Е”.

- 60 – Special model with flat surfaces.

- 70 – Special model with curved surfaces.

- 80 – Inserts, partitions and dividers.

Only the first and second pair is used, and they represent the type and subtype of the box.

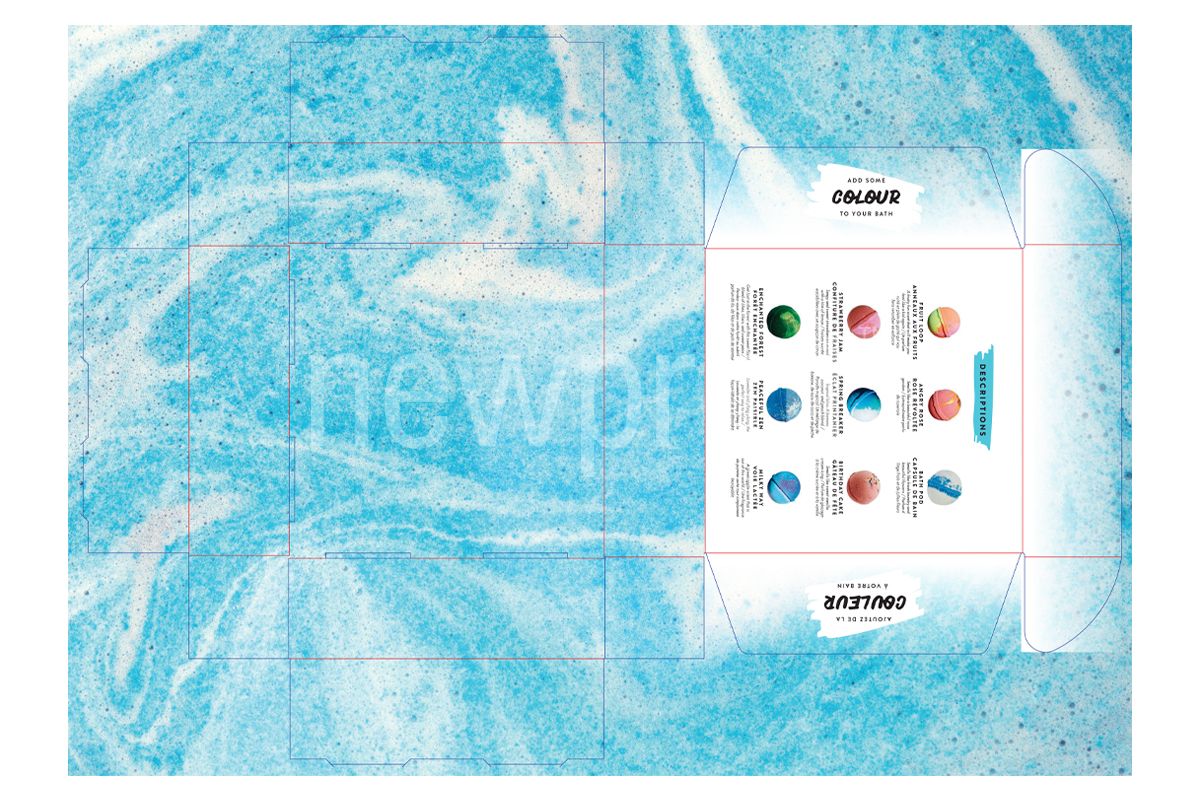

We understand that this may be overwhelming, but the good news is that you don’t have to know this information by heart. You should be aware that the ECMA code in the description of the box has meaning and can help you decipher what you are buying to make sure there is no misunderstanding between you and your supplier. ECMA standards offer one kind of universal language that can help everyone involved in the packaging business understand each other.

To conclude, if a printing company uses ECMA standards for their boxes, that does not, in any way, stand in the way of you getting unique custom packaging for your product. It only means that you can be sure that you will get the box you need, regarding certain elements and quality. ECMA carton styles for boxes are there to ensure that certain rules are followed when printing folding carton boxes and that customers will get the quality product that they need. Thus, standardization helps the industry move forward and improves the services printers have to offer.